Development of the PALLETsafe

Case Study

INTRODUCTION

Workplace-Worksafe is known for supplying innovative, cost-effective safety solutions to global providers of wind power solutions, ensuring the safety of its workers and products.

Where the industry typically uses standard solutions to protect or reduce hazards, we look at it from a health and safety angle. We know some of the products, mechanical components, electrical machinery in this industry is sensitive and costly. By considering alternative options other than the more traditional solutions, we develop innovative products that protect products/components in the same way that we would our people

We were approached by a client to provide an innovative solution to a transportation/logistical issue on a new offshore site.

CHALLENGES

The challenge surrounded a new transportation vessel and the newer type of offshore working patterns. Traditionally technicians would leave daily and return each night (subject to weather conditions). However, due to towers being built further offshore in deeper waters, the transfer time has increased which now limits the working day. New sites are moving more to vessels which can stay out at sea for a couple of weeks at a time, which means the products / consumables needed for the operations and maintenance are now being stored on the vessels.

The challenge posed was how to keep the smaller kit dry on the deck in all weather conditions. The ideal solution would be to have a waterproof pallet box, but these systems are not waterproof .

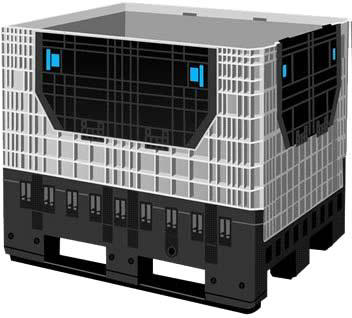

The brief from the client was to design a prototype that would be ready within a couple of weeks to trial on the new vessel before it went offshore. We had been given a brief that ideally the design would something similar to the pallet box below in Fig. 1.

We had to provide a solution which enabled the technicians to access various parts of the box without having to take the lid off, ideally whilst minimising the chance of the kit inside the box getting wet from rogue waves or rain on deck.

A key requirement was that the solution must be easy and simple to access, as the teams did not want to fight with systems that were difficult to open, or to have the lid blow away in the windy conditions typically experienced on offshore windfarms

PROS & CONS

Current options plastic pallet box

Pros

- Easily available

- Cheap

Cons

- Not waterproof

New system

Pros

- Could design to meet exact requirements

Cons

- Lengthy process

- Question as to whether we are re-inventing the wheel instead of modifying the current system

- Cost

Discussion took place as to what the ‘wish list’ would be for a new solution:

- Ability to store kit on deck without getting it wet

- Ability to hoist it on the tower crane from the vessel

- Easy/rapid access to the side of the crate

- Tough enough to withstand winter conditions on a vessel

- Access points need to be waterproof to keep products inside dry

SOLUTION

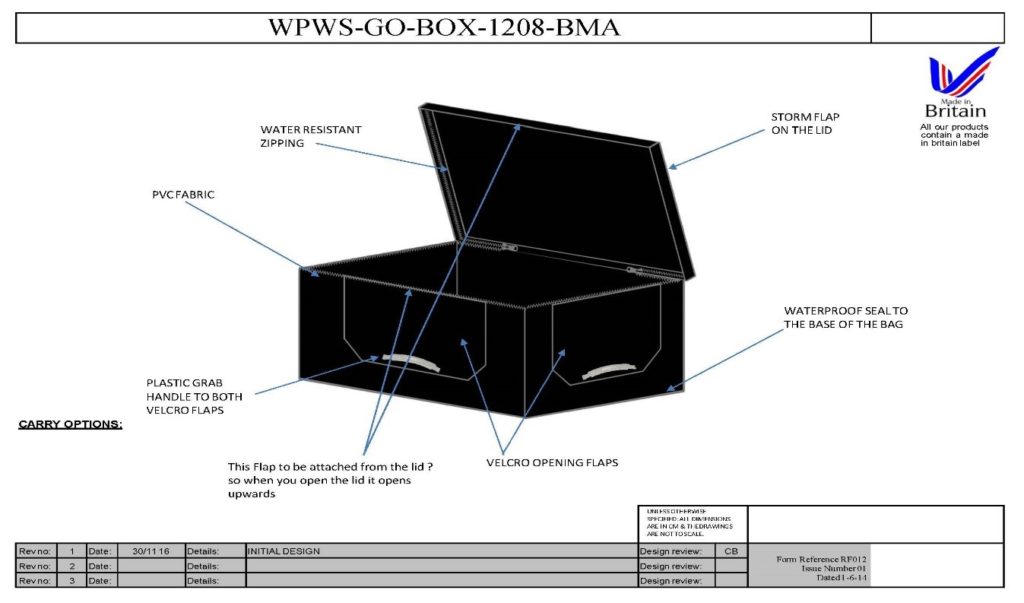

Workplace Worksafe came up with a simple but effective modification on a current system, what if we added a fully waterproof liner to the pallet box they had sourced?

By using our skilled machinists and experience in creating products that are fully waterproof, why not make the liner, but then add access points to marry up with the access points on the plastic pallet box?

This would then allow the teams to access the inner pallet box, and by having sealed access points which are watertight it enables easy access and keeps everything inside dry .

BENEFITS

The benefits of introducing the PALLETsafe system include:

- Uses a standard off-the-shelf product (pallet box) which is mass produced making it cheaper to purchase than having to purchase a whole new system

- Having a waterproof liner made the combined system watertight

- Simple, effective solution combining available solutions with new bespoke product design

RESULTS

The client was really happy with the combined solution, and has been using this for the last two years to carry consumables to and from offshore sites on the vessel.